Selection and assembly of racks

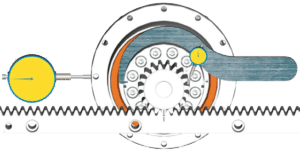

Calculation of the correct rack and pinion

Calculation of the correct rack and pinion

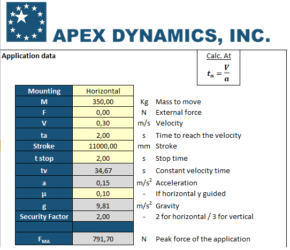

That is why Apex Dynamics offers the possibility to perform the calculations performed for you, with the starting point to achieve the desired specifications and accuracy. But more importantly, with 49 series of gearboxes and a huge selection of pinions and racks (the catalog is nearly 100 pages thick), we can make a tailor made product selection and propose the right components with regards to investment, technical and regional preferences. For example, the pinion can be mounted on the gearbox in 9 (!) ways.

The calculation that Apex Dynamics makes is well-arranged and can be used for the technical construction file.

Highest point marking

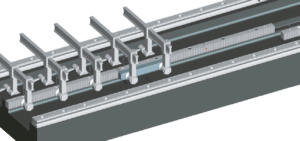

Apex Dynamics also provides a Dutch or English (even Spanish) Installation instruction, in which is explained how to assemble the components in the easiest way: From aligning and positioning the racks, adjusting the pinion to checking the adjustments.

Mounting bracket

These mounting racks are available from modules 1 to 10, for straight and helical toothed racks and in quality classes 4 and 5. If there is a need for even more accurate mounting, high-precision measuring pins can be supplied.

All specifications and accuracies of the racks and pinions of Apex Dynamics are transparent: The first pages of the catalog contain all tolerances such as hardening depth, material, straightness, squatness, surface roughness, etc. Also you’ll find here the DIN quality (linear accuracy), tooth quality, cure type and depth and itspost-processing. After the pinions section a table is listed with the maximum tangential force and torque for a specific quality of rack. Via this link you can download our complete catalogue.

For more information, please contact Apex Dynamics BV.

Calculation of the correct rack and pinion

Calculation of the correct rack and pinion