Robotic welding line automation thanks to the interplay of gearboxes, pinions and racks

Construction of greenhouses in the horticultural sector consist of a large number of steel elements that are partly welded together. Maurice Kassenbouw from the Netherlands has been using Yaskawa welding robots for the welding processes for twenty years. When these were due for replacement, the company expressed its wish to automate production as much as possible. In response to this demand, an entirely new production line has been developed where ten (10) handling and welding robots move on tracks via pinions over racks from Apex Dynamics. This accurate, automated solution has drastically reduced the number of people required for the production process.

Published in Aandrijftechniek September 2021

Greenhouse constructions for horticulture are constructed by combining a large number of steel elements with glass or plastic sheets. The beams and bars are connected to each other in such a way that a lightweight but strong construction is created that is fully tailored to the requirements of the horticulturist. In terms of size, durability, ventilation options, sun protection and so on.

From Produlas…

Tommy Hofkens is operational manager and co-owner and says: “The sales of robot installations to supplement our own welding went very well. After all, welding robots are indispensable for welding automation. They offer higher efficiency, lower labor costs and also contribute to a high and constant quality. In addition, the associated software is also being further improved, so that robots can be used for increasingly complex welding processes. This also makes them increasingly profitable for smaller series. In addition, based on our own experience, we were able to provide the right expertise when purchasing robots. After all, a welding process is complex and the quality depends on sophisticated various variables. The right robot and especially the right programming and fixture are therefore of crucial importance.”

… to Roboflex

By expanding the service package with the sale and commissioning of Yaskawa robots, the company has increasingly received requests to provide the handling systems around the robots in recent years. This enables customers to largely automate their production lines. Because Produlas saw a good future in this, it was decided to change the name Produlas to Roboflex; a name that better covers their activities. The company now mainly focuses on the engineering, production, assembly, delivery and commissioning of robot automation in the broadest sense of the word. As much as possible is produced in our own hall in Oosterhout; whether it concerns machining operations or assembly work. External parties are only engaged to coat the parts.

By expanding the service package with the sale and commissioning of Yaskawa robots, the company has increasingly received requests to provide the handling systems around the robots in recent years. This enables customers to largely automate their production lines. Because Produlas saw a good future in this, it was decided to change the name Produlas to Roboflex; a name that better covers their activities. The company now mainly focuses on the engineering, production, assembly, delivery and commissioning of robot automation in the broadest sense of the word. As much as possible is produced in our own hall in Oosterhout; whether it concerns machining operations or assembly work. External parties are only engaged to coat the parts.

Automation greenhouse construction line

Back to Maurice Kassenbouw who indicated to Roboflex that the Yaskawa robots needed to be replaced. Because this company is always working on innovation and technology, a 1:1 replacement of the robots was not an option. It was therefore soon decided to look at the possibilities for automation.

The first designs for a new production line were made at the digital drawing board. This starts with inserting the individual parts, such as top and bottom edges, diagonals, end plates and gusset plates in a mold. After a check, the mold with parts is passed on to the welding robots that make the welds and bend the product (provide pretension). After welding, the products are stacked by a specially designed crane. The mold is then transported back to the beginning of the line where the process is repeated.

Linear system

Final solution

In the final design, the production line includes the automated supply and removal of the various greenhouse parts and a large number of Yaskawa robots have been selected for the welding installation. Two large robots for handling parts that can measure up to 13 m (including the box sections) and four smaller handling robots. Six welding robots were also deployed per line to make the welded connections and specimens that take care of the welding. The handling and welding robots are placed on tracks that move along the line by means of a rack. A servo motor is used to drive each track with robot, which is also considered the seventh axis of the robot.

Large welding robots

The welding work is performed by 6 Yaskawa AR-3120 robots. These are the largest 6-axis robots in this range with a working range of 3,124 mm and a payload of up to 20 kg. The cables are fed through centrally and through a hollow shaft so that they cannot come into contact with the workpiece. This contributes to, among other things, better accessibility to the welding workpiece, but also a longer lifespan of the cabling.

All welding robots are equipped with an LSQ5 power source that does not use the usual inverters but works on the basis of ‘Direct Control Technology’ (DCT). This technology makes the required energy immediately available for the welding process without delay, which benefits the dynamics and accuracy of the welding process. The flexible fine-tuning is done by a CPU that continuously monitors the welding process and adjusts the current or voltage based on the findings. This not only leads to a high accuracy, but also to a lower heat development, which also benefits the quality of the weld.

For the handling of the parts, two GP120RLs and four GP180-120 robots are chosen. Here too, these are 6-axis robots, the first of which has a working range of more than 4 m and is suitable for payloads of up to 120 kg. The four smaller 6-axis robots have a working range of up to 2700 mm and a payload of 180 kg.

Modular controlling

Tommy Hofkens: “All robots are controlled via a YRC1000 controller. This makes synchronized operation of up to eight robots possible, which is certainly more than sufficient for this application. The robots are programmed in-house, which means that any adjustments as a result of process optimization at the greenhouse builder or changes in the configuration of the line can be quickly realized by us. Furthermore, the operation is so simple that the user does not have to program the robots himself. The customer can load the 3D model of the lattice girder into our own software. The robots are automatically programmed from these models and then controlled. This is certainly an important feature for this greenhouse builder, as all orders are customer-specific. In principle, each subsequent assignment is different with regard to the desired profiles, the dimensions and the number of welding points. Adjusting the robot programs is therefore a daily job.”

Gearboxes, pinions and racks

Finally, to set up an accurate and reliable production line, a stable construction is needed. For a line of several tens of meters long, this means extra attention for the gearboxes, pinions and racks on which the robots move. For this type of product, Roboflex has been working with Apex Dynamics for a long time.

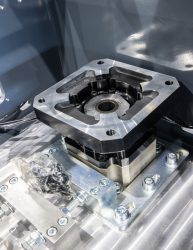

Apex Dynamics supplied four sets of AF100 planetary gearboxes with a ratio of 7:1 and six sets of AF140 planetary gearboxes with a ratio of 10:1 for the automated welding line. All gearboxes are equipped with a spline (DIN5480) output shaft with which a high accuracy and the desired power transmission can be realized.

Corresponding PU lubrication pinions are also supplied for the lubrication of the ten pinion/rack and pinion drives. This includes all connectors for the hoses that supply the lubricant.

Cooperation

Win-win.”

Publisher : Aandrijftechniek, Eisema Industriemedia

Text : Marjolein de Wit-Blok

Photo’s : Peter Roek