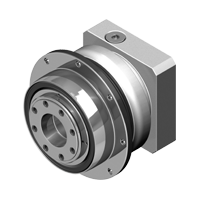

In line planetary

AH series

- Heavy duty gearbox

- Output flange ISO 9409

- Ratio 4 to 100

- Torque 24 Nm – 12.405 Nm

- Heavy Duty gearbox

- Black coated steel housing and output flange, aluminum motor adapter

- Steel output shaft, flange ISO 9409

- Helical gear technology

- Nominal Torques:

- T2N : 24 Nm - 12.405 Nm

- Ratios

- 1-stage : 4 / 5 / 7 / 10

- 2-stage : 16 / 20 / 21/ 25 / 28 / 31 / 35 / 40 / 46 / 50 / 61 / 70 / 91 / 100

- Low Backlash

- 1-stage : ≤ 1 arcmin (size 064 ≤ 2 arcmin)

- 2-stage : ≤ 2 arcmin (size 064 ≤ 3 arcmin)

- High Efficiency

- 1-stage : ≥ 97%

- 2-stage : ≥ 94%

- Easy mount

- Low noise

- Compact structure

- Sizes available: AH064 / AH090 / AH110 / AH140 / AH200 / AH255 / AH285 / AH355 / AH450

|

Model No. |

Stage | Ratio1 | AH064 | AH090 | AH110 | AH140 | AH200 | AH255 | AH285 | AH355 | AH450 | |

| Nominal output torque T2N | Nm | 1 | 4 | 100 | 205 | 380 | 765 | 1,415 | - | - | - | - |

| 5 | 85 | 185 | 325 | 660 | 1,225 | 1,905 | 3,505 | 6,250 | 11,520 | |||

| 7 | 60 | 135 | 260 | 515 | 980 | 1,530 | 2,630 | 5,045 | 9,585 | |||

| 10 | 24 | 55 | 160 | 315 | 700 | 1,070 | 1,810 | 3,345 | 7,160 | |||

| 2 | 16 | 100 | 205 | 400 | 805 | 1,485 | - | - | - | - | ||

| 20 | 100 | 205 | 400 | 810 | 1,495 | 1,990 | 3,660 | - | - | |||

| 21 | 90 | 195 | 345 | 700 | 1,295 | 2,005 | 3,685 | 6,525 | 12,405 | |||

| 25 | 90 | 195 | 345 | 700 | 1,295 | 2,005 | 3,685 | - | - | |||

| 28 | 60 | 205 | 405 | 820 | 1,510 | - | - | - | - | |||

| 31 | 60 | 135 | 280 | 560 | 1,050 | 1,620 | 2,590 | 5,280 | 10,510 | |||

| 35 | 75 | 195 | 350 | 705 | 1,310 | 2,030 | 3,725 | - | - | |||

| 40 | 40 | 96 | 220 | 615 | 1,260 | - | - | - | - | |||

| 46 | 24 | 55 | 160 | 335 | 660 | 1,005 | 1,700 | 3,400 | 7,125 | |||

| 50 | 50 | 120 | 275 | 715 | 1,325 | 2,050 | 3,765 | - | - | |||

| 61 | 60 | 135 | 300 | 585 | 1,095 | 1,670 | 2,675 | 5,445 | 10,795 | |||

| 70 | 60 | 135 | 300 | 585 | 1,095 | 1,670 | 2,675 | - | - | |||

| 91 | 24 | 55 | 160 | 345 | 660 | 1,005 | 1,700 | 3,400 | 7,000 | |||

| 100 | 24 | 55 | 160 | 345 | 660 | 1,005 | 1,700 | - | - | |||

| Emergency stop torque T2NOT | Nm | 1,2 | 4~100 | 3 times nominal output torque T2N | ||||||||

| Max. Acceleration torque T2B | Nm | 1,2 | 4~100 | 1,5 times nominal output torque T2N | ||||||||

| No load running torque (2) | Nm | 1 | 4~10 | 0,45 | 0,7 | 1,4 | 3,5 | 7 | 11 | 14 | 25 | 40 |

| 2 | 16~100 | 0,2 | 0,3 | 0,6 | 1,3 | 2,2 | 3,5 | 4,5 | 13 | 21 | ||

| Backlash (3) | arcmin | 1 | 4~10 | ≤ 2 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 |

| 2 | 16~100 | ≤ 3 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ||

| Torsional rigidity | Nm/ arcmin |

1,2 | 4~100 | 8 | 22 | 60 | 115 | 395 | 650 | 1,050 | 2,850 | 5,700 |

| Nominal input speed N1N | rpm | 1 | 4~10 | 5,000 | 3,600 | 3,600 | 3,000 | 2,700 | 2,400 | 2,100 | 1,500 | 1,000 |

| 2 | 16~100 | 5,000 | 4,600 | 4,600 | 4,000 | 3,700 | 3,400 | 3,100 | 2,500 | 2,000 | ||

| Max. input speed N1B | rpm | 1 | 4~10 | 7,000 | 6,000 | 6,000 | 5,000 | 4,500 | 4,000 | 3,500 | 3,000 | 2,500 |

| 2 | 16~100 | 7,000 | 7,000 | 7,000 | 6,000 | 5,500 | 5,000 | 4,500 | 4,000 | 3,500 | ||

| Max. radial load F2a(4) | N | 1,2 | 4~100 | 1,690 | 2,220 | 4,070 | 8,530 | 17,000 | 26,900 | 39,200 | 101,500 | 143,700 |

| Max. Tilting moment M2a(4) | Nm | 1,2 | 4~100 | 120 | 280 | 480 | 1,310 | 3,530 | 5,920 | 9,230 | 29,100 | 63,300 |

| Operating temperature | ºC | 1,2 | 4~100 | -10ºC ~+ 90ºC | ||||||||

| Degree of Protection | 1,2 | 4~100 | IP65 | |||||||||

| Lubrication | 1,2 | 4~100 | Synthetisch lubrication grease | |||||||||

| Mounting position | 1,2 | 4~100 | All directions | |||||||||

| Running noise (3) | dB(A) | 1 | 4~10 | ≤ 58 | ≤ 59 | ≤ 64 | ≤ 65 | ≤ 66 | ≤ 66 | ≤ 66 | ≤ 68 | ≤ 70 |

| 2 | 16~100 | ≤ 58 | ≤ 59 | ≤ 60 | ≤ 63 | ≤ 66 | ≤ 66 | ≤ 66 | ≤ 68 | ≤ 70 | ||

| Efficiency | % | 1 | 4~10 | ≥ 97 % | ||||||||

| 2 | 16~100 | ≥ 94 % | ||||||||||

- Ratio ( i = N in / N out )

- Backlash is measured at 2% of Nominal output torque T2N.

- These values are measured by gearbox with ratio = 10 (1-stage) or ratio = 100 (2-stage) at 3.000 rpm without load.

- Applied to the output flange center at 100 rpm.

- Continuous operation is not recommended.

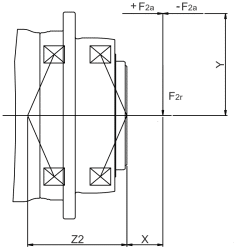

Maximum tilting moment:

| Size | AH064 | AH090 | AH110 | AH140 | AH200 | AH255 | AH285 | AH355 | AH450 | |

| Z2 (mm) | 63.7 | 84.5 | 106.2 | 90 | 122.8 | 133.2 | 175.5 | 220.6 | 275.3 | |

Applied to the output flange center at 100 rpm.

| Model No. | AH064 | AH090 | AH110 | AH140 | AH200 | AH255 | AH285 | AH355 | AH450 | ||||||||

| Ø (1) (C3) | 1-st. | 2-st. | 1-st. | 2-st. | 1-st. | 2-st. | 1-st. | 2-st. | 1-st. | 2-st. | 1-st. | 2-st. | 1-st. | 2-st. | 2-st. | 2-st. | |

| 8 | kg*cm2 | - | 0.10 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 11 | 0.17 | 0.16 | - | 0.17 | - | - | - | - | - | - | - | - | - | - | - | - | |

| 14 | 0.21 | 0.20 | 0.53 | 0.21 | - | 0.53 | - | - | - | - | - | - | - | - | - | - | |

| 19 | 0.63 | - | 0.68 | 0.63 | 1.83 | 0.68 | - | 1.83 | - | - | - | - | - | - | - | - | |

| 24 | - | - | 4.52 | - | 5.04 | 4.52 | 5.63 | 5.04 | - | 5.63 | - | - | - | - | - | - | |

| 28 | - | - | - | - | 6.33 | - | 7.18 | 6.33 | - | 7.18 | - | - | - | - | - | - | |

| 32 | - | - | - | - | 8.73 | - | 10.10 | 8.73 | 12.63 | 10.10 | - | 12.63 | - | - | - | - | |

| 35 | - | - | - | - | 14.04 | - | 15.54 | 14.04 | 17.75 | 15.54 | 17.35 | 17.75 | 28.18 | 20.80 | - | - | |

| 38 | - | - | - | - | 19.05 | - | 21.35 | 19.05 | 23.26 | 21.32 | 23.61 | 23.26 | 28.18 | 27.05 | 23.60 | - | |

| 42 | - | - | - | - | - | - | 23.20 | - | 25.40 | 23.20 | 25.50 | 25.40 | 30.52 | 28.95 | 25.37 | 30.37 | |

| 48 | - | - | - | - | - | - | 56.07 | - | 61.02 | 56.07 | 61.22 | 61.02 | 66.85 | 64.66 | 89.35 | 96.45 | |

| 55 | - | - | - | - | - | - | - | - | 88.51 | - | 88.86 | - | 94.91 | - | 102.00 | 109.06 | |

| 60 | - | - | - | - | - | - | - | - | - | - | - | - | 117.73 | - | - | 117.75 | |

(1) ø = Input shaft diameter

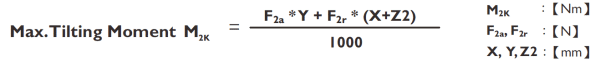

AH series:

| Afmeting | AH064 | AH090 | AH110 | AH140 | AH200 | AH255 | AH285 | AH355 | AH450 |

| D1 H7 | 20 | 31,5 | 40 | 50 | 80 | 100 | 100 | 120 | 155 |

| D2 | 31,5 | 50 | 63 | 80 | 125 | 140 | 160 | 200 | 250 |

| D3 h7 | 40 | 63 | 80 | 100 | 160 | 180 | 200 | 250 | 315 |

| D4 h7 | 64 | 90 | 110 | 140 | 200 | 255 | 285 | 355 | 450 |

| D5 | 79 | 109 | 135 | 168 | 233 | 280 | 310 | 385 | 490 |

| D6 x spoed x diepte | M5 x 0.8P x 8 | M6 x 1P x 10 | M6 x 1P x 11 | M8 x x1.25P x15 | M10 x 1.5P x 20 | M16 x 2P x 25 | M20 x 2.5P x 31 | M24 x 3P x 32 | M30 x 3.5P x 40 |

| D7 | 88 | 120 | 147 | 180 | 249,5 | 302 | 332 | 415 | 530 |

| D8 | 4,5 | 5,5 | 5,5 | 6,6 | 9 | 13,5 | 13,5 | 17,5 | 22 |

| L1 | 8 | 15 | 15 | 15 | 16 | 16 | 16 | 35 | 24 |

| L2 | 19,5 | 30 | 29 | 38 | 50 | 66 | 75 | 80 | 85 |

| L3 | 4 | 7 | 7 | 7,5 | 8,5 | 13,5 | 16,5 | 20 | 20 |

| L4 | 5 | 7 | 8 | 10 | 12 | 18 | 20 | 45 | 60 |

| X in graden | 45 | 45 | 22,5 | 30 | 30 | 24 | 24 | 22,5 | 30 |

| Y in graden | 45 | 45 | 22,5 | 30 | 30 | 24 | 24 | 22,5 | 30 |

| Z | 8 | 8 | 12 | 12 | 12 | 12 | 12 | 16 | 12 |

| U in graden | 45 | 45 | 45 | 30 | 30 | 22,5 | 22,5 | 30 | 30 |

| V graden | 45 | 45 | 45 | 30 | 30 | 22,5 | 22,5 | 30 | 30 |

| W | 8 | 8 | 8 | 12 | 12 | 16 | 16 | 12 | 12 |

(1) Input dimensions vary according to motor flange. Please contact Apex Dynamics for details.

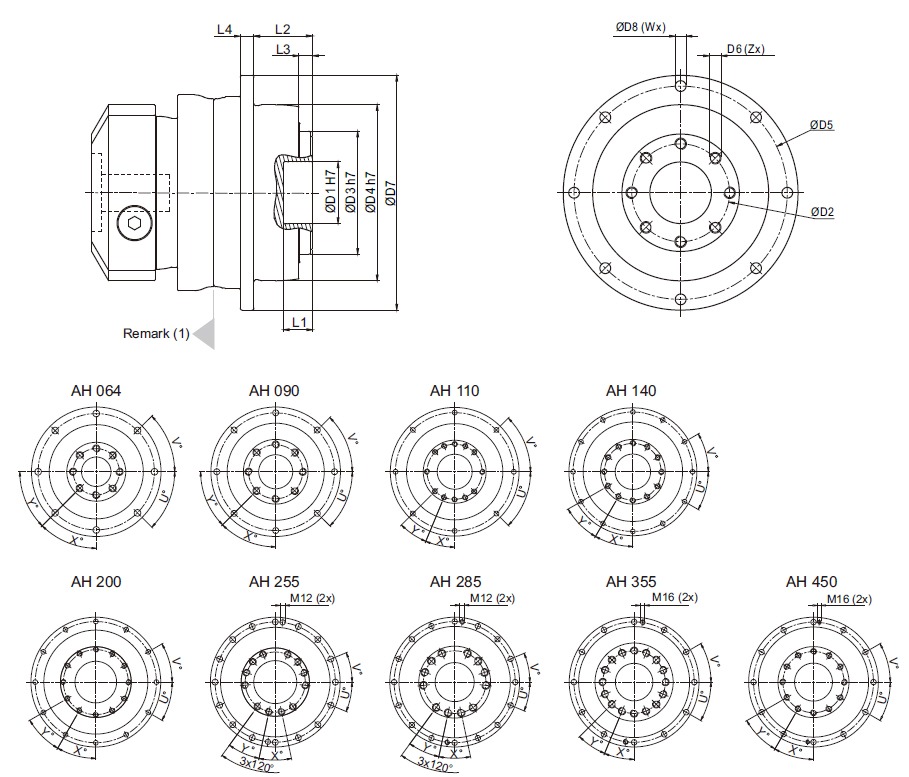

Flange As - AH series:

| Afmeting | L1 | L2 | D3 h6 | D6 | L9 | L10 | Order Coder |

| AH064 | 33 | 23 | 16 | M5 | 4,8 | 12,5 | FLS-AH064-S16 |

| 22 | M8 | 7,2 | 19 | FLS-AH064-S22 | |||

| AH090 | 41 | 30 | 22 | M8 | 7,2 | 19 | FLS-AH090-S22 |

| 32 | M12 | 10 | 28 | FLS-AH090-S32 | |||

| AH110 | 51 | 38 | 32 | M12 | 10 | 28 | FLS-AH110-S32 |

| 40 | M16 | 12 | 36 | FLS-AH110-S40 | |||

| AH0140 | 54 | 38 | 40 | M16 | 12 | 36 | FLS-AH140-S40 |

| 55 | M20 | 15 | 42 | FLS-AH140-S55 | |||

| AH200 | 73 | 52 | 55 | M20 | 15 | 42 | FLS-AH200-S55 |

| 75 | M20 | 15 | 42 | FLS-AH200-S75 | |||

| AH255 | 150 | 123 | 90 | M24 | 18 | 50 | FLS-AH255-S90 |

Need help with your application? Our specialists are happy to use their years of experience to assist you in selecting the right products.