Racks and Pinions Apex: transmission from a single source

The expansion of our product range with Apex Dynamics racks and pinions was received exceptionally well by the market. The gained expertise in robotics resulted in a competitive offer that integrates seamlessly with the market demand. Some customers only need to find their way that is why we list in this article all about the racks and pinions. Especially with the overview of our various construction options can be to your advantage. Prefer personal contact? We can discuss your application personally, please contact us for an appointment.

The expansion of our product range with Apex Dynamics racks and pinions was received exceptionally well by the market. The gained expertise in robotics resulted in a competitive offer that integrates seamlessly with the market demand. Some customers only need to find their way that is why we list in this article all about the racks and pinions. Especially with the overview of our various construction options can be to your advantage. Prefer personal contact? We can discuss your application personally, please contact us for an appointment.

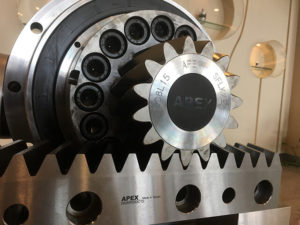

How rack and pinions work

A rack is a rectangular bar which on one side is provided with teeth, such as a gear; basically a gear with an infinite radius. The pinion, a small gear wheel, which is in contact with the teeth roll over the rack and this is how linear movement is made. (The linear movement is made by either the pinion or the rack).

Applications of racks in the industry

Applications of racks in the industry

Racks are in particular used in the industry where a rotating drive must be converted into a linear displacement. We see them often used in robotics, cutting machines, milling machines and machining tables. In these markets, the rack often stands still and the pinion rolls over it.

The implementation of the rack in the market is so diverse that there arose different names for such device. We call the rack just rack in English. People who are working for the Dutch, German or French markets will hear the names Tandheugel (NL), Zahnstange (Du) and Crémaillère (FR) in the vocabulary. The pinion has less different names but here also sometimes the different languages can be confusing; Rondsel (NL), Ritzel (Du) and Pignon (Fr).

How to calculate a rack and pinion system

How to calculate a rack and pinion system

Calculating a Rack and Pinion system is quite difficult because in many cases, a gearbox is part of the drive. Therefore a large amount of factors affect the final result, which means there are many variables in the calculation.

Common variables in the calculation of the rack and pinion applications are:

- Mass to move

- Speed of movement

- Acceleration

- Friction

- Desired safety devices vertically and horizontally

- Desired lifetime

From this information you can select the appropriate module for the rack. Next, make a choice for straight or helical teeth, which hardness, which accuracy, which material needs to be used, the length of the rack, the diameter of the pinion, and so on. The diameter of the pinion is, more frequently limited, and determined by the gearbox which it is mounted on.

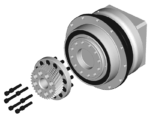

Mounting the pinion to the gearbox

If you have made a choice, it’s time for the next step, mounting the pinion. There are obviously different ways to attach the pinion to the gearbox and each has its own advantages and disadvantages. The possibilities are extensive, below we give the pros and cons of each type of transmission in an overview. The last column shows the corresponding gearboxes of Apex Dynamics.

| Transmission | Advantage | Disadvantage | Remark |

| Key | Simple Cheap Fast |

Backlash by key Limited torque Small diameter restricted by key |

Mountable on AB / AF / PII series. Complete supplied by Apex |

| Key with chuck | Simple Fast. Backlash-free |

Small diameter restricted by key Length of the hub by clamping bush |

Mountable on AB / AF / PII series. Complete supplied by Apex |

| heat shrinking pinion | Simple Fast. Backlash-free |

Not interlocking In case of wear or breakage all replaced Choice unalterably |

Highly accurate applications |

| Clamp | Simple Backlash-free |

Small diameter limited by clamping bushing Risk of tilting in case of incorrect mounting Not interlocking |

Mountable on AB / AF / PII series |

| ISO9409 flange (adjacent, teeth plate) |

Normalized Backlash-free Compact |

Small diameter is limited by flange | Mountable on AD / PD / AH series Complete supplied by Apex |

| ISO9409 flange (Offset, welded plate) |

Normalized Backlash-free Small diameter possible |

Larger diameter is limited by the mounting holes | Mountable on AD / PD / AH series Complete supplied by Apex |

| Welded | Backlash-free Small diameter possible |

When worn or broken renew all Choice unalterably Customized solution |

|

| Spline DIN5480 | Fast assembly Higher torque than with key |

Demontage moeilijker Kleine diameter beperkt door as Speciale uitgaande as van reductor nodig |

Mountable on AF-S3 and KF-S3 series Complete supplied by Apex |

| ISO9409 Curvic Plate | Simple Maximum flexibility Backlash-free |

Mountable on AD / PD / AH series Complete supplied by Apex |

Getting started with racks and pinions

Getting started with racks and pinions

As you can see, Apex Dynamics is able to supply all components for complete mechanical drive systems; gearboxes, racks, pinions and lubrication system. The great advantage is that everything is supplied from a single source in the proper precision, quality, performance, hardness, and other preferences. And all with an unrivalled delivery time in the market.

Obviously, each servomotor can be mounted.

Now you have an excellent idea of the potential but making the right choice takes a lot of time. We can save you this time by explaining to you the application, and put together all necessary ingredients and options. This way we get in no time to the optimum choice for your application and you are fully informed about all possibilities.

About one thing you can be sure, also for racks and pinions Apex is running faster.

Press release, April 19, 2017

Applications of racks in the industry

Applications of racks in the industry How to calculate a rack and pinion system

How to calculate a rack and pinion system

Getting started with racks and pinions

Getting started with racks and pinions