High-End printing press

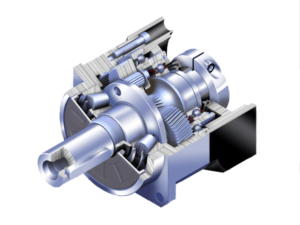

Apex Dynamics gearbox is superior in High-End printing press. The best way to show what the gearboxes of Apex Dynamics makes unique is to give a practical case, and recently we had a nice example. One of the largest printing press manufacturers in the world started to use servo controlled technique to optimize the behaviour of the rollers inside the printing press. The accuracy to print an image is obviously leading, this sets high demands for the mechanical transmissions.

That is why they choose a gearbox with helical gears with the first pre-selection.

In subsequent tests was even decided to put a fan between the motor and gearbox for cooling. This is obviously not ideal, the increased airflow could lead to contamination of the print.

At equal application circumstances and speed, the Apex gearbox kept it’s head cool

Some figures in this story; The gearboxes of the competition got 95°C at first stage, after installing the fan they became 85°C. At the same circumstances and speed the Apex gearbox stabilized at 60°C (without cooling fan)! One of the main reasons is that Apex gearboxes have a high efficiency. The following features make this happen:

- The seal on the input side (high speed side) is separated from the ball bearing. This seal is mounted at the smallest diameter (minimum of circumferential speed, so minimum friction) on a hardened and grinded surface.

- The ball bearing on the input side is mounted between the input shaft and the output shaft. The speed which the ball bearing runs is relative: at 3.000 rpm input speed with ratio 3:1, the ball bearing is running 3.000 – 1.000, which means only 2.000 rpm. With our colleagues this bearing is running at 3.000 rpm.

Apex Dynamics runs faster,

and in this example it is certainly not only in terms of service!