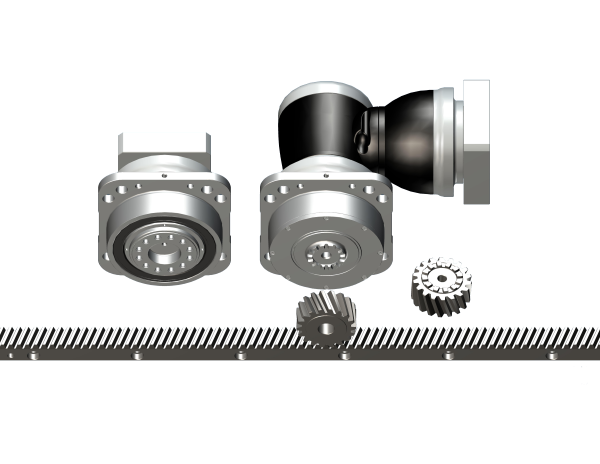

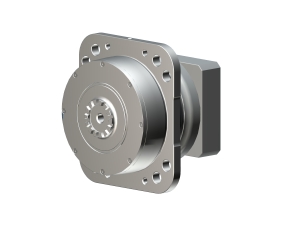

Apex introduces new product series for High-End drives: The MGO/MGOH series

Apex continues to expand the range in the already extensive program. In doing so, we respond to innovations and demands from the market. This new MGO series is capable of transmitting the highest forces and can therefore rightly be called a real “powerhouse”. In this article, we will discuss the advantages and specific features.

High power density

Why is it possible to achieve an extremely high power transmission?

Why is it possible to achieve an extremely high power transmission?

The MGO/MGOH series (MGO/MGOK/MGOH/MGOHK) are firstly equipped with larger mounting holes, to achieve a simple adjustment of, for example, a pinion on a rack. Secondly, the internal construction of the gearbox is optimized for high forces and finally, the series is equipped with 8 bolt holes to mount the gearbox in the application. If this is also equipped with the Curvic-Plate pinion, the highest forces and torques in the industry can be transferred. “With the MGO/MGOH series, Apex has even more possibilities in the market. With the highest possible force density, significant advantages in constructions are realized,” says Sales Manager Eric Megens. “Because Apex Dynamics produces the gearboxes, pinions and racks itself, we can calculate the torques and precision of the linear system, accurate to the Nm and micrometer!”

Features:

- Maximum power density

- Enhanced axial and radial load

- High torsional rigidity

- Long-Term Persistence of Low Backlash

- High efficiency / optimized moment of inertia

- Identical input/output rotation direction with Hypoid right angle K-series

- Standard ISO9409 flange or Curvic output shaft

- Widest and most extensive range in the market, always a suitable solution!

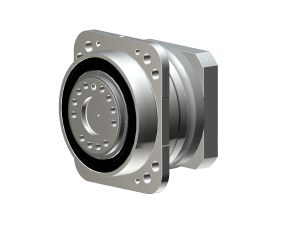

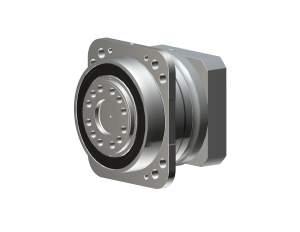

MGO-series

The output flange follows the ISO9409 standard, but it can also be equipped with our patented Curvic-plate flange for direct mounting of a pinion for the highest force density.

Optionally, we can supply a shaft attachment, which is mounted directly to the flange, so that you can realise an output shaft.

Naturally, the MGO/MGOK series is equipped with helical gearing and the planet carrier has 3 planetary wheels to transmit the torque.

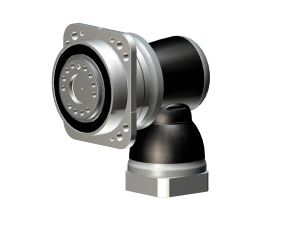

MGOH-series

The output flange follows the ISO9409 standard, but it can also be equipped with the so-called Curvic-plate flange for direct mounting of the pinion for the highest force density.

The MGOH/MGOHK series is equipped with helical gearing and the planet carrier has 4 planetary gears to transfer the maximum possible torque.

Curvic plate

Also interested in this unique product that sets a new standard in power transmission and precision? For more information about this series of gearboxes in your application, please contact Apex Dynamics.