Measuring system corrects falling glass drop

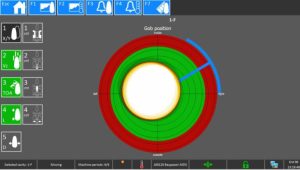

STT Products develops customized, innovative, technical solutions for the manufacturing industry. Companies in the manufacturing industry are increasingly faced with changes that affect the production process. More demand for flexibility, shortage of technical personnel and need for sustainable production methods mean that optimum efficiency and full automation are required. In this case: the system ensures that the drop (white circle) falls in the middle of the target.

Glass industry

For the glass industry (production of glass bottles), STT Products has developed measuring and correction systems on behalf of and in close cooperation with XPAR Vision. One of these is the measuring and control system GobAssist-BTC. This concerns a combination of sensors that can digitally visualize and influence the mold temperature and the (speed, position and shape of the) falling glass drop. This measuring system makes it possible to stabilize the production process, for example with feedback loops. This allows bottles to be produced with a more uniform wall thickness and therefore also with less glass. This not only saves material, costs and energy, but is also more sustainable for the environment.

Savings through weight reduction

With the GobAssist-BTC, deviations in the process can be detected and corrected at an early stage. Before this system was implemented, deviations were only discovered at the end of the production process, which resulted in many more out-of-spec products that had to be discarded, which costs a lot of extra material (glass). The savings are in the big numbers: with a weight reduction of 0.5 grams per bottle and a production line of 200 million bottles per year, the saving quickly amounts to 100,000 kg of glass.

Bevel gear box, rack and pinion

Apex Dynamics supplied the low-backlash bevel gearboxes with hollow shaft, racks and pinions for this system and made the calculations for this setup. The ambient conditions (high temperature, gases, vibrations, speed) were taken into account when selecting the components. This linear system positions the measuring system so that the glass droplet falls above the center of the mold, so that the wall thickness of the bottle is ultimately more uniform and less glass is needed per bottle.

Source : Automation magazine

Source : Automation magazine

| Collaboration | STT Products BV |

| XPAR Vision BV | |

| Apex Dynamics BV |