Dynamax, the calculation software from APEX DYNAMICS

Dynamax is designed to be a powerful tool for calculating various applications that include Apex Dynamics products. Whether you are looking for the ideal gear ratio, the right motor selection or optimizing the efficiency of your drive system, Dynamax offers you the tools you need to work quickly and accurately.

With Dynamax you can easily select the right drive components and optimize their efficiency. With its intuitive interface and advanced calculation algorithms, Dynamax is the perfect partner for engineers, designers and technicians who strive for optimal performance and reliability.

In short, with Dynamax you can take your drive systems to a higher level and carry out projects faster and more efficiently. Are you ready to simplify your calculations and increase your productivity? Discover Dynamax from Apex Dynamics today!

Calculation software for various applications

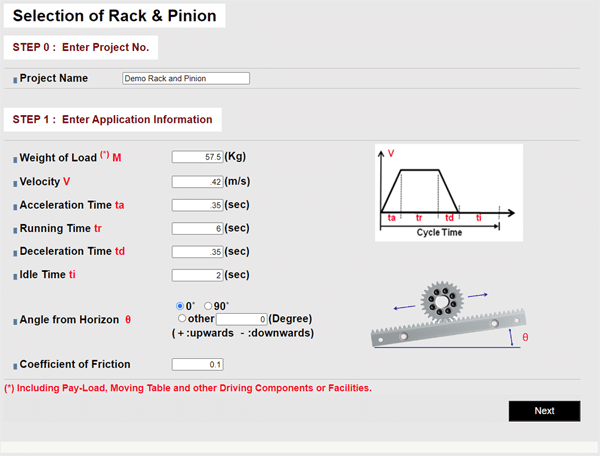

Dynamax has been specially developed to make calculations for a number of standard motion applications. These motion applications are:

- Rack & Pinion

- Ball-screw

- Turning Table

- Conveyor Belt

- Turning Table with Gear Drive

- Conveyor Belt with Pulley Drive

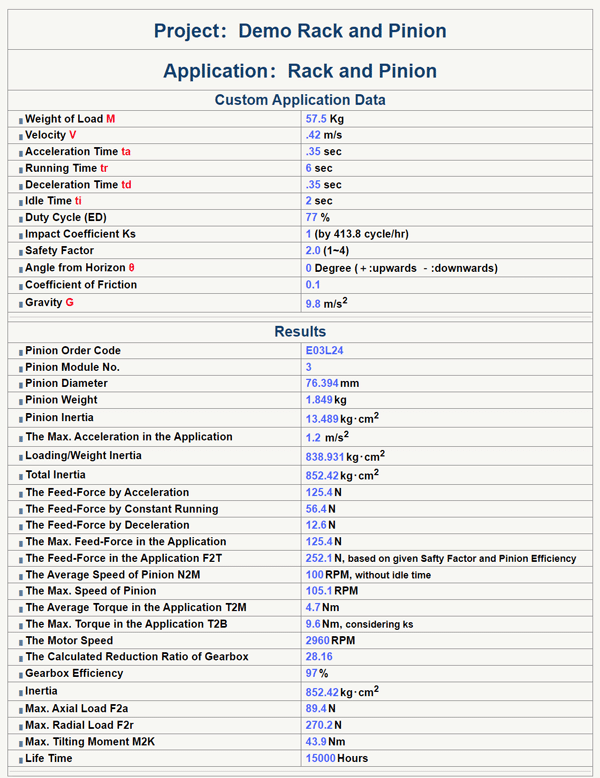

The software guides you through the various application parameters, of course you must know what the application is and what you want to achieve.

Complex rack and pinion calculations

The rack and pinion drive is – due to Apex Dynamics’ enormous portfolio – difficult to work out, because it is an equation with many variables. Nine types of pinions with different numbers of teeth can be mounted on the 73 different series of gearboxes. And that includes spur and helical teeth. That is why we are happy to perform these calculations for you. So that you get the most optimal drive. This is one of the specializations at Apex Dynamics and has no equal in the market.

Servomotor selection

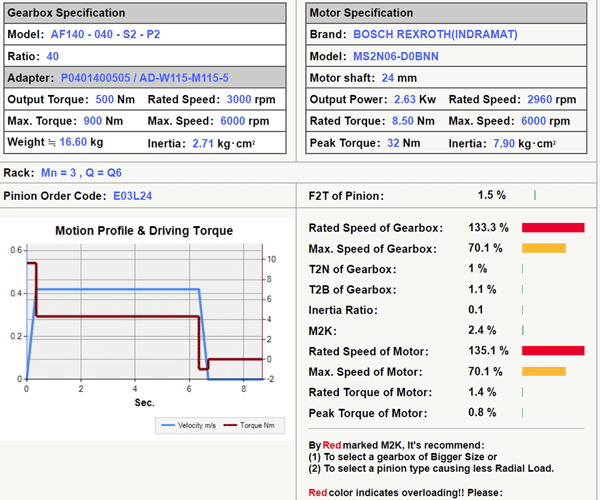

The advantage is that not only the basic calculations are done, but that our servomotor database is linked to them. This makes it easy to choose the motor in Dynamax, after which it automatically selects the size and transmission ratio. The last step shows graphically where the reserves are, but also where the drive is critical. This is done with red, orange and green bars, so that this is immediately visible.

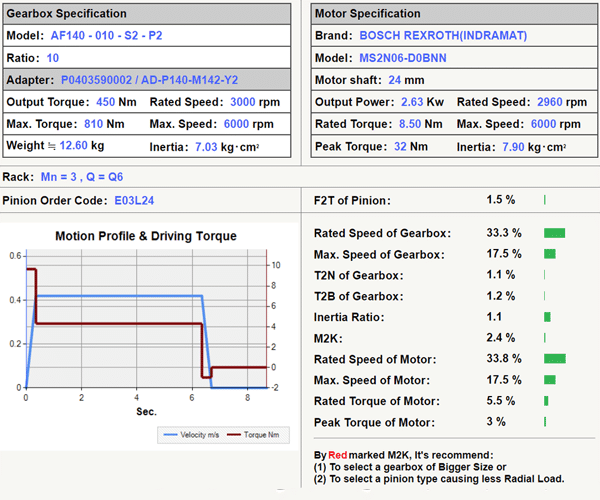

The above ratio does not appear to be optimal, given the red and orange bars. Below is the calculation for ratio 10, which is more optimal:

If you are not satisfied with the result, you can simply click back to the design specification, motor choice and gearbox choice.

Construction file

If the calculation meets your requirements, simply give the document a name and download the construction file, for example.

If you are unable to find a good solution? Send the design specifications together with the desired servomotor data to Apex Dynamics BV and we will be happy to make the calculations for you. And as our relations expect from us: you don’t have to wait days for it, but it is often in your mailbox within 24 hours.

Free available

Dynamax can be used freely and without logging in, just like our configuration software DesignTool.

If you would like more information, please contact Apex Dynamics or start the calculations via the Dynamax button on our website or directly via this link.