How do you assess the accuracy of a gearbox?

Accuracy, what exactly do we mean by that? Even for technical specialists, the accuracy of a servo transmission is complex. That is why we explain in this article which factors determine the accuracy of a gearbox and we make a detour to the so-called transmission error.

Evaluate Gearbox Accuracy

Backlash in a gearbox is influenced by various factors that can be traced back to the precision of the individual gears. In particular, the roundness of the gears, pitch deviations, pressure angle deviations and spiral angle deviations play a role.

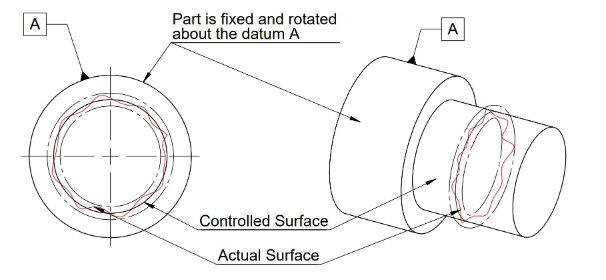

Runout

This refers to the variations in the radius of the gear over a full revolution. When parts of the gear are smaller than the designed diameter, the backlash increases.

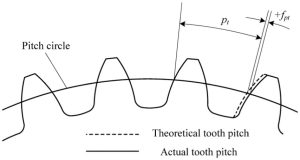

Pitch deviation

Also called tooth-tooth error, this concerns the deviations in position between successive teeth. A larger space between the teeth increases the clearance, while less space reduces it.

Pressure Angle

The force that is transferred between gears is not completely perpendicular to the diameter, but at a specific angle, the pressure angle. Deviations in this angle can negatively affect the accuracy of the gearbox.

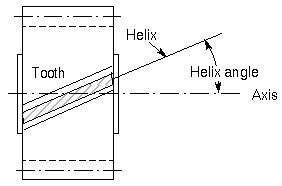

Helix Angle

Helical gears have a larger contact area between the teeth, resulting in less noise and smoother operation. However, deviations in the helix angle can either increase or decrease the backlash.

Transmission error and efficiency

Although backlash is an important indicator of accuracy, it only provides a partial picture. Another important factor is transmission error, which represents the difference between the expected and actual position of the gears. This error is influenced by roundness and pressure and helix angle deviations. In many cases, transmission error is a better measure of the overall quality of a gearbox.

In addition, the efficiency of the gearbox also plays a crucial role in performance. This is influenced by roundness and pitch deviations, but especially by the geometry of the gears themselves, such as pressure and helix angle. Optimizations in these parameters not only contribute to more accurate operation, but can also lead to higher torques and improved performance.

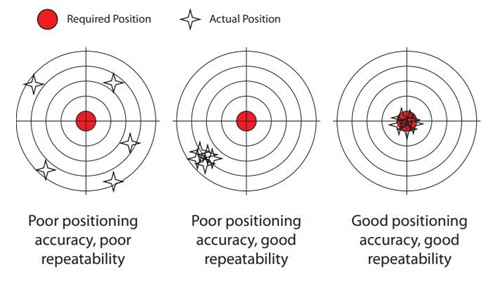

Accuracy vs. Repeatability

Assessing the accuracy of a gearbox requires more than just measuring backlash. While backlash is a useful measure, a broader understanding of transmission errors and other precision parameters provides a more complete picture of a gearbox’s quality. Innovations in gear design and control over micro-geometries provide opportunities to improve both accuracy and efficiency, resulting in higher performance and longer gearbox life.

The figure below illustrates the difference between accuracy and repeatability. The left diagram shows a low-quality gearbox, while the right diagram shows the performance of a high-quality gearbox.