Optimal gearbox and industrial robot combination

The word robot was first used by Czech writer Karel Čapek in his play R.U.R., which stands for Rossum’s Universal Robots. It was written in 1920 and is derived from the Czech word robota, which means ‘work’ or ‘mandatory labour’. In this section, we will only deal with industrial robots, which are mainly used in industry. The COBOT, a robot that works together with people, and robots in surgery, household, catering, etc., for example, are not taken into account.

For each type of robot, we recommend a type of gearbox from Apex Dynamics with its most important characteristics. In this article we discuss the following industrial robots:

- Single belt or H-bridge

- Cartesian, Cartesian, Linear or XYZ Robot

- Single arm, Articulated arm or robotic arm

- Delta, parallel or kinematic robot

- Automatic Guided Vehicle (AGV)

- Autonomous Mobile Robots (AMR)

- Scara robot

Gearbox for Single belt or H-bridge robot

The optimal gearbox for a Single Belt or H-bridge robot comes from the PAII series.

Due to the low inertia of the gearbox, high dynamics can be achieved, with backlash having a minor influence on accuracy. This is a fairly simple solution and this is where this economy series comes in.

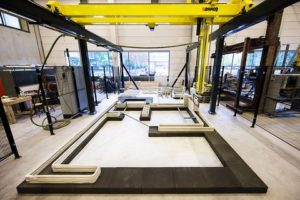

Gearbox for Cartesian, Linear or XYZ Robot

A Cartesian robot is an industrial robot whose three main control axes are linear (i.e. they move in a straight line instead of rotating) and are perpendicular to each other. The three axes correspond to up-down, forward-back and left-right. Among other advantages, this mechanical arrangement simplifies the solution of the robot control arm. It has high reliability and precision when working in three-dimensional space. As a robotic coordinate system, it is also effective for horizontal movements and for stacking bins.

The standard Cartesian robot has 3 axes.

Which gearbox?

The optimum gearbox for a Cartesian, linear or XYZ robot comes from the AF series.

Low backlash and high stiffness to cope with the higher mass inertias, together with a strong bearing to absorb the high radial load that occurs.

Gearbox for single arm, articulated arm or robot arm

A robotic arm is a mechanical manipulator with similar functionality to a human arm. A robot arm consists of a number of segments that are connected to each other by joints, and between which translations and/or rotations are possible. These parts together form a kinematic chain. The way in which the parts are connected to each other and how they can move among themselves determines the number of degrees of freedom of the robot arm.

At the end of the robot arm is the tool that allows the robot to perform a task, such as gripping or turning something. A freestanding Articulated Arm Robot often has 6 free axes, if it is placed on a track, it has 7 axes.

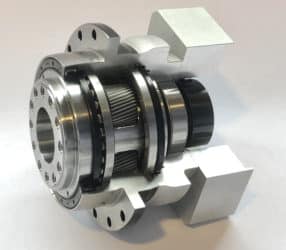

The optimal gearbox for a single arm, articulated arm or robot arm robot comes from the AH series.

High precision for accuracy and high torques. The gearbox has an output flange for extra rigidity.

Gearbox for Delta, Parallel or Kinematic Robot

A delta robot is a 3-axis robot suitable for small work areas and fast applications. The shafts are connected to a shared joint above and below the arms to maintain power and speed. The first delta robot was invented in the early 1980s by Professor Raymond Clavel and his team at the Ecole Polytechnique Federale de Lausanne (Switzerland). The standard Delta robot has 3 axes, with a central rotation it becomes 4 axis.

The optimum gearbox for a Delta, parallel or kinematic robot comes from the AP series.

Extremely low backlash to avoid tracking errors, along with high torques and low inertia for high dynamic drive.

Gearbox for Automatic Guided Vehicle (AGV)

The optimum gearbox for an Automatic Guided Vehicle (AGV) comes from the PD/PL series.

Because this application is not super accurate and has low dynamics, a medium accuracy is sufficient. (Adjustment takes place through the markers) The large bearings can absorb high radial loads.

Gearbox for Autonomous Mobile Robots (AMR)

An autonomous mobile robot is a type of robot that is able to understand its environment and move through it independently. AMRs differ from their predecessors, automated guided vehicles (AGVs), which rely on tracks or predefined paths and often require operator supervision.

AMRs use a sophisticated array of sensors, artificial intelligence, machine learning and route planning computers to interpret and navigate their environment without relying on wired power. Because AMRs are equipped with cameras and sensors, if they encounter an unexpected obstacle while navigating, such as a fallen box or crowd of people, they will use a navigation technique such as collision avoidance to slow down, stop or reroute their path around the object and then continue with their task.

The optimal gearbox for an Autonomous Mobile Robots (AMR) comes from the GL series.

Because the accuracy must be higher than with an AGV, we choose the GL series for its high accuracy, high radial loads and starting torque compensator. As a result, the outgoing pulley turns in the opposite direction to the motor and the drive is more controlled.

Gearbox for Scara robot

The SCARA is a type of industrial robot. The acronym stands for Selective Compliance Assembly Robot Arm or Selective Compliance Articulated Robot Arm. Due to the parallel axis direction of the SCARA, the arm is slightly flexible in the X-Y direction but stiff in the Z direction, hence the term selective compliance. This is advantageous for many types of assembly work, for example inserting a round pin into a round hole without blocking. The second feature of the SCARA is the articulating, two-joint arm arrangement, similar to human arms, hence the commonly used term “hinged”. This allows the arm to be extended in tight spaces and then retracted or “folded”. This is advantageous for moving parts from one cell to another or for loading or unloading process stations that have been shut down.

SCARAs are generally faster than comparable Cartesian robotic systems. Their single pedestal mount requires a small footprint and provides an easy, unhindered form of mounting. On the other hand, SCARAs can be more expensive than comparable Cartesian systems and the control software requires inverse kinematics for linearly interpolated movements. However, this software is usually included with the SCARA and is usually transparent to the end user.

The optimal gearbox for a SCARA robot comes from the AP series.

Extremely low backlash for accuracy, along with low inertia for high dynamic control.

This robot-type overview is undoubtedly not complete and there are also many sub-variants and exotics. However, it should be clear that Apex Dynamics always has a suitable solution with its 69 product series. Our specialists are happy to advise you on the right gearbox for your application. Feel free to contact us.