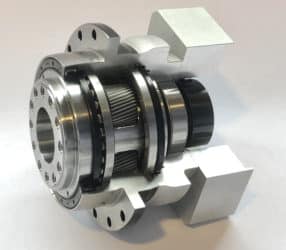

High torque flange gearbox: AP series

How do you transfer more torque, with extremely low backlash, in a limited space? For this purpose, Apex Dynamics introduced the high-value AP High Torque series onto the market with an ISO9409 output flange.

How do you transfer more torque, with extremely low backlash, in a limited space? For this purpose, Apex Dynamics introduced the high-value AP High Torque series onto the market with an ISO9409 output flange.

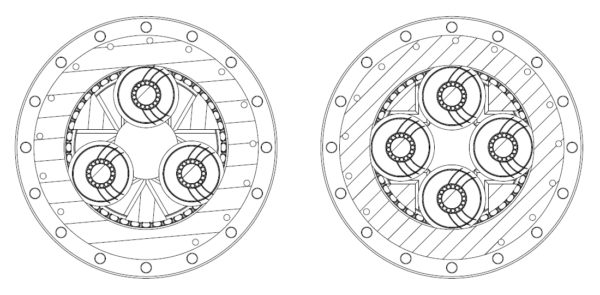

This series has 4 (!) Planet gears, which is 1 more than other commonly used series such as AD, AH and PD. The AP High Torque is therefore ideal for demanding, high-precision applications such as (delta) robots, linear systems and in the automotive industry.

Since 1781, engineers and technicians have been working to further perfect and optimize the planetary gearbox. Because the driven sun wheel often drives 2 or 3 planet gears – which rotate in a hollow gear – the force is processed over all these gears, resulting in a compact, but very strong gearbox.

Planetary gearbox innovation

Because of all this attention, major steps have been taken in the construction, the material, the hardeningoptions, seals, bearings and production accuracy. This is clearly visible in the different series of gearboxes from Apex Dynamics. Partly because of the various patents and inventions in the gearbox, such as the pump rings, rotating input bearing and one-piece planet carrier, the planetary gearboxes from Apex Dynamics can handle the highest torques.

High torque handling with limited space

But what if these torques are not high enough? If you want to process even more torque, but you don’t have more space? And you don’t want or can’t go to a larger gearbox because of the larger inertia, which slows down the dynamic behaviour? Especially for these kind of applications, Apex Dynamics has launched the AP series, a High-Torque version with an ISO9409 output flange.

Why can it transmit more torque than, for example, the type PD (flange gearbox medium end, spur teeth), AD (flange gearbox high end, helical teeth), AH (flange gearbox high end, helical teeth, extreme low backlash)?

In all of these gearboxes, the sun gear drives 3 planet gears, which rotate in a hollow gear. In the AP, the sun wheel drives 4 (!) gears, which also rotate in a hollow gear. This allows you to transfer theoretically 33% more torque. And that also with an extreme low backlash.

Because there are 4 planet gears in the AP, the ratio in the last stage is always 4 or 5.5 absolute. That is why the total transmission ratio of the AP is always a multiplication of 4 or 5.5.

Application AP high torque gearbox

Application AP high torque gearbox

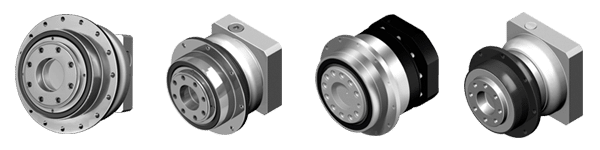

The AP High Torque is used in high-precision linear systems, robotics such as a Delta Robot and the automotive sector. If needed, the AP can also be applied with a curvic-plate interface, the APC, and is also available in right-angle versions.

For more information and advice, please contact Apex Dynamics BV.

Application AP high torque gearbox

Application AP high torque gearbox